HOW TO MAKE PCB BY HAND.

pcb making by hand

This is a very very crude and old technique. it is wonderful for prototyping the small RF projects. This is a unique in a sense there is no through hole. the component is surface mounted but use normal components. It has maximum copper. It is more rigid and solid then sticking the copper-pads on the copper plain. Here component are also not hanging loose over the copper pad. the computer generated pcb are more efficient, accurate & repeatability. But, hand made pcb are designer, small kit builder, new hobbyist friendly.

I have seen that these hand made PCB works wonderfully for the RF devices. I use it exlusively.

We need good copper clad boards. Better start with single sided glass epoxy based board. That is mechanically strong, copper is little thicker then the normal ply based copper board.

I use oil-paint to paint the tracks. My recommendation is to use two colors one for tracks, pads etc and one for plain copper ground. That way we do not mix-up while painting.

First draw the ckt on plain paper. correct it for all mistakes. put the circuits in small small portions/modules. That will help finding the faults or isolating the RF stages.

Then have actual transistors, resitors, inductors, capacitor, connectors etc you want to use for their dimentions.

Once again see how this components will be placed on board, what will be their size, orientations, shieldings etc. Signal flow directions. Vcc lines. Controls, indicators etc.

Oscillators always need to be shielded even if it is xtal controlled. xtal filters needs more ground plane.

Be it RF amp or AF amp using a single transistors you need atleast minimum3-5 pads for placing components around transistors. IC needs atleast whatever its pin counts, so on and on.

After placing components with minimum distance & not crowding them you can create the copper islands on papers. check it with components size. See your whole project in simple modules say input RF band pass filter, Rf amplifier, filter, diode detector, xtal oscillator, Af amplifiers, IC amplifier , power supply, connectors. Thus ckt are understood as a modules unit. then giving transistor ic parts number makes easy for us to loacte them in PCB & ckt and for future discussions. Thats it !!! we compartmentalized our pcb into module after module. When you are placing the components see your circuit diagram. refer to it. check you are not missing any components. Visualize it. Thus finally on paper your board is visualized and drawn. use 1 inch graph paper that will increase accuracy.

Now take the pcb. measure it cut according to the size you realized on paper. wash it, clean for dirt thumb prints, greece etc. file the edges clean smooth it.

Generally i use 3 inch by 5 inch size boards. Not hard and fast but this size is ok. On this draw one inch greed lines. These boards are not small nor big. Enough for a small project.

Sometimes we have to cut the board according to our box or the project in which we already want to add & fit into. there we can use 3-4 small sized boards and put them on vertical stack. usable. imagine. when you use the sealed can/ shieldings then signals do not see others and do not interfere. That's good enough. Sometimes for shielding put 1-2 cm high copper board that also works good.

When designing see that you have maximum copper ground area. It should not be broken between two module that create complications & earth loop. You have connectors at edges, there is round holes for the pcb. if these holes needs to be isolated then plan it early.

Before etching do not drill holes. That part do not cover with color and it will etch-out and drill hole. So that nut-bold/screw used for that hole will not touch our pcb ground.

After pcb is drawn checked i let is sleep for 12 hours/ over night. Next day i check for any mistakes or things i remember to put at hindsight.

If there is any variations, just rub the boards with ink-erasur/ alcohol that part of whole pcb board and wash with water dry and do once again with pencil & markers.

Use ruler for straight lines. go slow do not make mistake. Now foto graph that for future reference.

pcb coloring/painting is simple. use the finest knibbed edge / paint brush. dip and brush fir island, tracks. let it be straight lines boxes do not let it blot & spread out etc.

let is dry.

Then use the different colour paint and paint the copper ground that you do not want to etch. At this time, mistakes are done/happens as colours touches already painted tracks. so be careful. if you make mistake, note it down on paper and move on. when the colour dry at that time remove that colour with small kife very carefully.

So, the board will start drying within a hour but do not touch it. let it dry over-night. next day these board is ready.

If oil stains your hand wash it with soap.

Next day when the board is dry see that it is clearly dry paint is not soggy. if need arise let it dry for another day. After then put that pcb into fecl3 ferric clride solution/ or HCl hydro-cloric acide and add h2o2 hydrogen paroxide ( available from medical store) and about half hour one hours it will etch. time to time stirr it. is it bubling or not, then add more h2o2 and it will start bubbling. When the pcb is etched take it out and see are you able to see track from back side. then its done.

wash your pcb with simple water, soap. have little bit of scratch-papers, i use from kitchen. and remove oil paints. Do a visual check. have continuity check with mutlimeter, if needed cut the track with knife. Now you can not put pcb into etching solutions.

here is the vedio of painting the pcb full 12 minutes process. click here.

https://www.youtube.com/watch?v=61WyLP8NHds

After this you should wrap etched copper pcb in dry cloth or paper till you use it.

For tools i used, marker pen, knife, ruler, paint brush, paper drawings.

to be continued... etching fotos and end result.

RESULT

the pcb was etched successfully. here is the part2 vedio of pcb making. it looks nice.

https://www.youtube.com/watch?v=T7KEtFLjVts

use fresh acid, fresh hydrogen peroxide. add the hydrogen peroxide generously and it will bubble up. wait wait then it will etch fast. never used the acid used earlier. do not use more acid then dippin the pcb. keep the tray as small as possible, more acid more hydrogen peroxide needed. so use small container that dips the pcb and thats it.

always keep water and cloth to wash acid if it touches your body. use the goggles , white glass for eye protections.

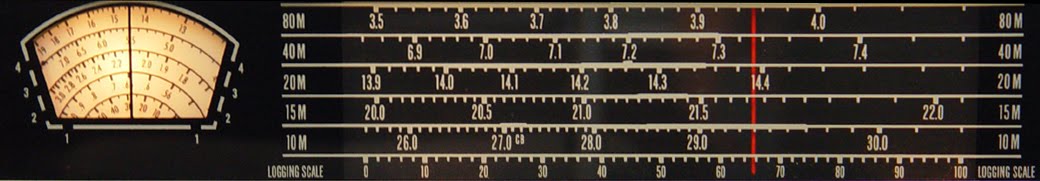

(by the way i have populated the board and DC receiver based on poliyakov design is ready here see the fotograph and write up will be here and vedio will be here :- link to be included later on )

|

| 3686kc poliyakov receiver. |

|

the wheel is successfully invented use it.